If your sewing machine needle is refusing to move, don’t panic! This common issue can often be resolved with some simple troubleshooting steps. Here’s a concise introduction to getting that needle moving again:

A sewing machine needle may fail to move due to a bent or improperly installed needle, debris obstructing mechanisms, lack of lubrication, or other mechanical issues. To fix the problem:

- Check that the needle is straight, undamaged, and correctly inserted

- Clean out any lint, thread, or fabric caught in the bobbin area

- Apply sewing machine oil to lubricate moving parts

- Ensure the machine is receiving power from the foot control

- Consult your manual for steps to realign or recalibrate the machine

Ready to get your sewing machine back in working order? Let’s dive into the details.

Understanding the Sewing Machine

Sewing Machine Basics

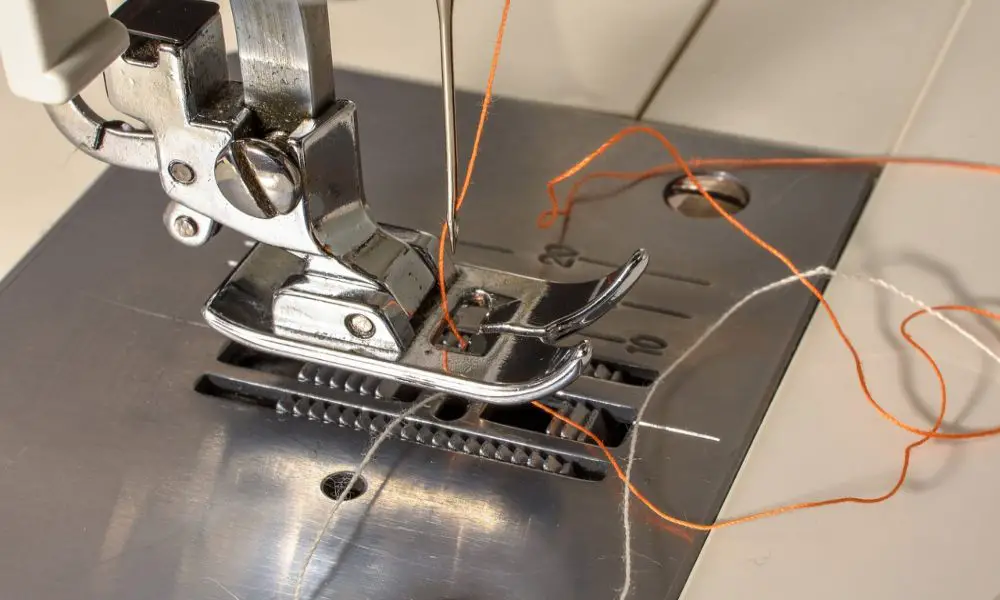

A sewing machine is a device that uses a needle to stitch fabric together with thread. It is a complex machine with many parts, but understanding the basic components can help troubleshoot issues like a sewing machine needle not moving. The main parts of a sewing machine include the needle, bobbin system, presser foot, needle plate, hand wheel, and foot pedal.

The Role of the Needle

The needle is the most important part of the sewing machine. It is responsible for piercing the fabric and creating a hole for the thread to pass through. The needle’s position can be adjusted to create different types of stitches. The needle is held in place by the needle bar and can be changed out for different sizes or types of needles depending on the fabric being sewn.

The Bobbin System

The bobbin system is responsible for creating the bottom thread that is used to stitch the fabric. The bobbin is a small spool of thread that is inserted into the bobbin case. The thread is then pulled through the bobbin tension and wound onto the bobbin winder shaft. The bobbin winder is then engaged, and the thread is wound onto the bobbin. The bobbin is then inserted into the bobbin case and placed into the machine.

Presser Foot and Needle Plate

The presser foot is a metal piece that holds the fabric in place as it is being stitched. It applies pressure to the fabric, which helps it move through the machine smoothly. The needle plate is a metal plate that sits underneath the presser foot and has a small hole in the center for the needle to pass through. The fabric is fed through this hole as it is being stitched.

The Hand Wheel and Foot Pedal

The hand wheel is a large wheel on the right side of the sewing machine that is used to manually move the needle up and down. It can be used to adjust the needle position or to help pull the thread through the fabric. The sewing machine is started and stopped using the foot pedal. It is connected to the motor of the machine and controls the speed of the machine.

It is crucial to comprehend the fundamental parts of a sewing machine to solve problems such as the needle not moving. By knowing how each part works together, it is easier to identify the cause of the problem and find a solution.

Identifying the Problem

When a sewing machine needle is not moving, it can be frustrating and confusing. However, identifying the problem can help you fix it quickly and get back to your sewing project. This section will provide some guidance on identifying the problem with your sewing machine needle not moving.

Symptoms of a Stuck Needle

There are a few symptoms that can indicate a stuck needle. If your sewing machine is turned on, but the needle is not moving, it could be due to a stuck needle. Additionally, if you hear a grinding or clicking noise when you try to sew, this could also indicate a stuck needle. Finally, if the needle is not moving, but the motor is running, this is another sign of a stuck needle.

Common Sewing Machine Problems

There are a few common sewing machine problems that can cause the needle to become stuck and not move. These include:

- Broken Needle: A broken needle can cause the needle to become stuck in the fabric or the machine, preventing it from moving.

- Needle Position: If the needle is not in the correct position, it may become stuck and not move. Make sure the needle is properly inserted into the needle clamp and that the needle is not bent or damaged.

- Bobbin: A problem with the bobbin can cause the needle to become stuck. Make sure the bobbin is properly inserted and that the thread is not tangled or caught.

- Presser Foot: A problem with the presser foot can cause the needle to become stuck. Make sure the presser foot is properly attached and that the fabric is properly positioned.

- Bobbin Thread: A problem with the bobbin thread can cause the needle to become stuck. Make sure the bobbin thread is properly inserted and that the thread tension is correct.

- Needle Plate: A problem with the needle plate can cause the needle to become stuck. Make sure the needle plate is properly attached and that there are no obstructions or debris.

By identifying the symptoms and common problems associated with a stuck needle, you can quickly diagnose the issue and take steps to fix it.

Troubleshooting Steps

If your sewing machine needle isn’t moving, there are various measures you can implement to address the problem. This section will cover the most common troubleshooting steps for a sewing machine needle that is not moving.

Checking the Needle Position

The first thing you should check is the needle position. Make sure the needle is properly inserted and tightened in the needle clamp. If the needle is not properly inserted or tightened, it may not move when you press the foot pedal.

Inspecting the Thread

The next thing to check is the thread. Ensure that the thread is correctly threaded through the machine. Check that the thread is not tangled or caught on any of the machine’s parts. If the thread is tangled or caught, it may prevent the needle from moving.

Examining the Bobbin

Another common cause of a sewing machine needle not moving is an issue with the bobbin. Check that the bobbin is properly inserted and threaded. Make sure the bobbin is not tangled or caught on any of the machine’s parts. If the bobbin is tangled or caught, it may prevent the needle from moving.

Assessing the Stitch Length

Finally, check the stitch length. If the stitch length is set too short, the needle may not move because it is not given enough time to complete a full stitch. Adjust the stitch length to a longer setting and try again.

If none of these troubleshooting steps resolve the issue, consult your sewing machine manual or take your machine to a professional for repair.

Remember to always turn off your machine and unplug it before attempting any troubleshooting. Safety first!

By following these troubleshooting steps, you can quickly identify and resolve the issue of a sewing machine needle not moving.

Maintenance and Prevention

To prevent your sewing machine needle from not moving, it is essential to maintain and take care of your machine. Here are some tips to keep your machine running smoothly.

Cleaning and Oiling

Regular maintenance, such as cleaning and oiling, can prevent sewing machine issues, such as a stuck needle. Be sure to clean the lint and dust from the machine and oil it regularly. Check your sewing machine manual for detailed guidance on cleaning and oiling.

Proper Threading

Incorrect threading of the machine can cause the needle to jam or not move. Ensure that the thread is correctly threaded through the machine, including the needle thread and bobbin thread. Make sure there are no knots or tangles in the thread to prevent the needle from stopping.

Needle Replacement

A broken needle or a needle that is bent can cause the machine to stop moving. Replace the needle regularly, especially if you are working on a large sewing project. Refer to your machine manual for the correct needle size and type for your project.

Fabric Considerations

The type and thickness of fabric can also cause the needle to stop moving. Be sure to use the appropriate needle size and type for your fabric. A needle that is too small or too large for the fabric can cause the needle to jam or not move.

Regular maintenance and care of your sewing machine can prevent many issues, including a needle that won’t move. By cleaning and oiling your machine, properly threading it, replacing the needle regularly, and considering the fabric you are working with, you can keep your sewing machine running smoothly.

FAQ Frequently Asked Questions

Why Won’t My Sewing Machine Needle Move?

There are several reasons why a sewing machine needle may not move. One common reason is that the machine is not threaded correctly. If the thread is not threaded correctly, the needle won’t move.

Another reason could be that the machine is not turned on or is not receiving power. Check to make sure the machine is plugged in and turned on. Additionally, the needle may be bent or damaged. In this case, the needle will need to be replaced.

What Are Common Reasons for a Sewing Machine Motor Running but the Needle Not Moving?

If your sewing machine’s motor is running but the needle isn’t moving, there could be a few potential reasons for this issue. One reason could be that the machine is not threaded correctly. Another reason could be that the needle is not properly inserted into the machine. The needle may also be bent or damaged. In some cases, the machine may need to be serviced or repaired.

How Do I Troubleshoot a Sewing Machine Hand Wheel That Won’t Move?

If the sewing machine hand wheel won’t move, there are a few things you can try to troubleshoot the issue. First, make sure the machine is properly threaded. If the machine is threaded correctly, check to see if there is any thread or lint caught in the machine. This can cause the hand wheel to become stuck. Additionally, the machine may need to be oiled. Check the machine’s manual for instructions on how to oil the machine.

What Are Some Possible Causes of a Singer Sewing Machine Motor Running but Nothing Moving?

If a Singer sewing machine motor is running but nothing is moving, there are a few possible causes. One cause could be that the machine is not threaded correctly. Another cause could be that the needle is not properly inserted into the machine. The needle may also be bent or damaged. In some cases, the machine may need to be serviced or repaired.

What Should I Do If My Sewing Machine Starts Then Stops?

If your sewing machine starts and then stops, there are a few things you can try to troubleshoot the issue. First, make sure the machine is properly threaded. If the machine is threaded correctly, check to see if there is any thread or lint caught in the machine. This can cause the machine to stop working. Additionally, the machine may need to be oiled. Check the machine’s manual for instructions on how to oil the machine.

Why Won’t My Sewing Machine’s Handwheel Turn?

If your sewing machine’s handwheel won’t turn, there are a few things you can try to troubleshoot the issue. First, make sure the machine is properly threaded. If the machine is threaded correctly, check to see if there is any thread or lint caught in the machine. This can cause the handwheel to become stuck. Additionally, the machine may need to be oiled. Check the machine’s manual for instructions on how to oil the machine.

It is important to note that if you are experiencing issues with your sewing machine needle not moving, it is best to consult the machine’s manual or contact a professional for assistance. Attempting to fix the issue yourself could cause further damage to the machine.

Conclusion

A sewing machine needle not moving can be extremely frustrating, but the issue can usually be resolved by methodically troubleshooting the problem. Before starting, ensure that the sewing machine is threaded correctly and that the thread is not tangled or caught. Also inspect the needle and make sure it is inserted correctly and not damaged. Issues with the bobbin such as improper threading or tangling could also prevent the needle from moving.

If none of the common issues are found, consult your sewing machine’s manual for further troubleshooting tips specific to your model. The manual can provide guidance on properly oiling the machine, replacing parts, and making adjustments. With patience and care, the root cause of a seized needle can typically be discovered and fixed. Proper cleaning, maintenance, and use will prevent problems and keep your sewing machine happily stitching for years to come.

What troubleshooting steps have you found most effective when dealing with a sewing machine needle that won’t move? Share your tips and experiences in the comments below to help fellow sewing enthusiasts tackle this common issue!

***

Main image: Pixabay