Oiling your sewing machine regularly is crucial for keeping it in top condition. This simple maintenance task ensures your machine’s moving parts operate smoothly, preventing friction, wear, and potential damage. Here’s a quick overview:

- Unplug the machine and remove any fabric or threads

- Use the lubricant recommended in your manual

- Apply oil sparingly to moving metal components

- Run the machine briefly to distribute the oil

- Wipe away any excess before stitching again

Ready to get into the details? Let’s explore how to keep your sewing companion well-oiled and humming happily.

Find the Right Sewing Machine Oil

Not all oils are suitable for lubricating sewing machines. Using the wrong lubricant can lead to buildup, gumming, and potential damage over time. Always consult your machine’s manual and use only the type of oil specified by the manufacturer.

A high-quality synthetic oil formulated explicitly for sewing machine use is ideal for most modern sewing machines. These oils have excellent lubricating properties without the risk of degrading or leaving sticky residues.

If you have an older or vintage sewing machine, a pure mineral oil may be recommended instead of synthetic varieties. Mineral oil is a natural lubricant that works well with the materials found in vintage machines.

A Note on Substitutes

You may be tempted to use a household oil like olive or vegetable oil in a pinch. However, these cooking oils can go rancid and attract dust, leading to potential gunking over time. Sticking the manufacturer’s recommendations for safe, long-term use is best.

Prepare for Oiling

Before applying any lubricant, take a few simple preparatory steps:

- Unplug the machine from power to avoid any accidental starts

- Remove the needle, bobbin case, and any fabric scraps or threads

- Use a small brush or compressed air to clean out any lint or debris buildup

Having a clean surface prevents contaminants from mixing with the new oil. It also allows you to clearly see all the components that need lubricating.

Oil Sewing Machine Moving Parts

With your machine prepped, it’s time to apply the oil. Use a fresh, lint-free cloth or a small brush to transfer just a drop or two of oil onto each of the following areas:

Needle Bar and Presser Foot

The needle bar is the vertical metal rod that the needle attaches to. Apply oil along its length and pivot points where it meets other components. Also lubricate the presser foot and its surrounding attachments.

Bobbin Area

Lift the bobbin cover and apply a drop of oil into the bobbin case area, including the rotary hook race (or shuttle race on older machines). This allows the bobbin to turn smoothly while stitching.

Thread Guides and Tension Discs

A few drops of oil on any thread guides, tension discs, and take-up levers help the thread feed smoothly through these components during use.

Interior Gears, Cams, and Shafts

Carefully lubricate any exposed interior gears, cams, shafts, and other moving metal pieces with oil. Don’t over lube – just a drop or two is sufficient.

The key is applying a thin, even coat to all moving surfaces without oversaturating one area. Too much oil can drip onto your projects or lead to buildup over time.

Distribute the Fresh Oil

With the lubricant applied, run your machine for 3-5 minutes without any thread or fabric. This allows the oil to fully disperse and penetrate all those tiny crevices and moving parts.

Finally, a clean cloth should be used to remove excess oil collected on the exterior surfaces and under the needle plate. Your sewing machine is now freshly oiled and ready for smooth, quiet operation!

When to Oil Your Machine

As a general guideline, sewing machines used frequently should be oiled once a month. For those who sew only occasionally, be sure to oil the machine before any extended periods of use after storage.

Maintaining this simple routine and keeping your machine lint-free is the key to extending its life and ensuring excellent stitch quality on every project.

FAQs

Can I use cooking oil to lubricate my sewing machine?

While cooking oils may work in a pinch, they are not recommended for regular sewing machine lubrication. Over time, these oils can go rancid, attract dust and lint, and cause gummy buildup in your machine. Stick to the oil types specified in your manual.

How do I oil an older or vintage sewing machine?

Vintage sewing machines tend to do best with pure mineral oil rather than modern synthetic varieties. Consult your machine’s manual, as mineral oil was commonly recommended for proper lubrication of older models.

Where can I find the recommended oil for my machine?

The owner’s manual should list the exact type of sewing machine oil to use. If you no longer have the manual, contact the manufacturer directly or check with an authorized dealer for the recommended lubricant for your specific machine model.

Is there any way to over-oil a sewing machine?

Yes, using too much oil can lead to over-lubrication issues. Excess oil can drip onto fabric, leave stains, and attract lint over time. Always apply lubricant sparingly to moving parts only.

***

So there you have it – the simple steps to keep your sewing machine running smoothly with routine oiling. Do you have any other tips for easy machine maintenance? Let me know in the comments!

***

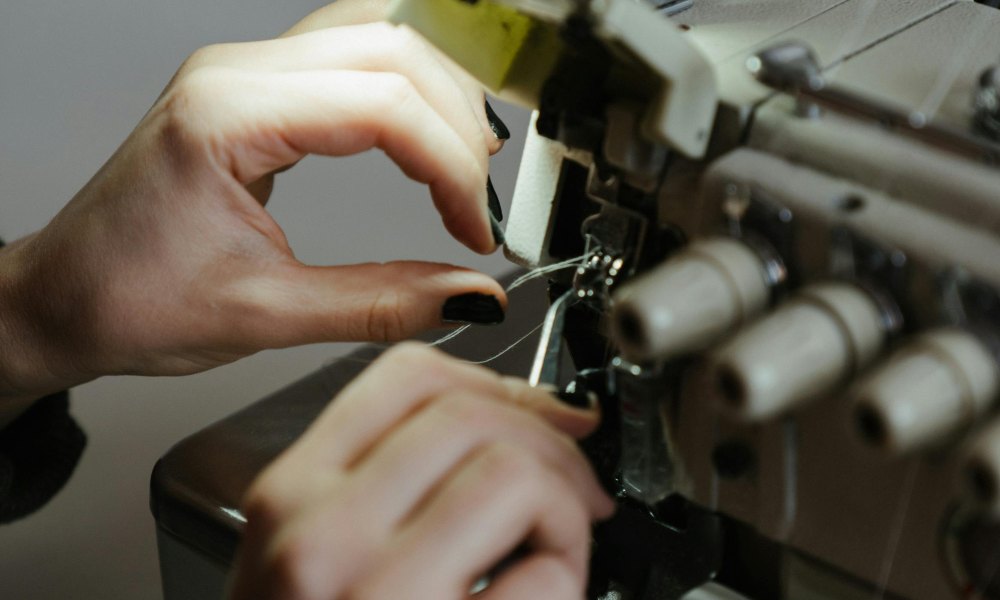

Main image: pexels